Industrial electrical resistors combined with effective thermostats

Industrial electrical resistors for a perfectly controlled heating water in harsh environments.

Industrial electrical resistors are a component of considerable importance for the development of heat within industrial systems. Their study and design must be carried out accurately in order to ensure effective operation and minimize the losses that may develop within the circuit in which they are installed.

As for this type of components, Gnali Bocia represents a company with experience in the creation and control of the entire production cycle.

As for this type of components, Gnali Bocia represents a company with experience in the creation and control of the entire production cycle.

Sizing and use of industrial electrical resistors

The materials that can be used within an electrical circuit can be divided into two macro categories: insulators and conductors. As the name implies, insulators tend to oppose the passage of current while conductors guarantee and allow the passage of this. Since the current is defined as the displacement of electric charges, in particular of electrons, we speak of electric resistance when there is a component that opposes this movement.

At the base of the behavior of a circuit in the presence of one or more electrical resistors there are certainly Ohm's laws, which are necessary both for the effective sizing of the system and to be able to calculate the values of the main electrical quantities, the voltage (in Volts) and the current intensity (in Amperes).

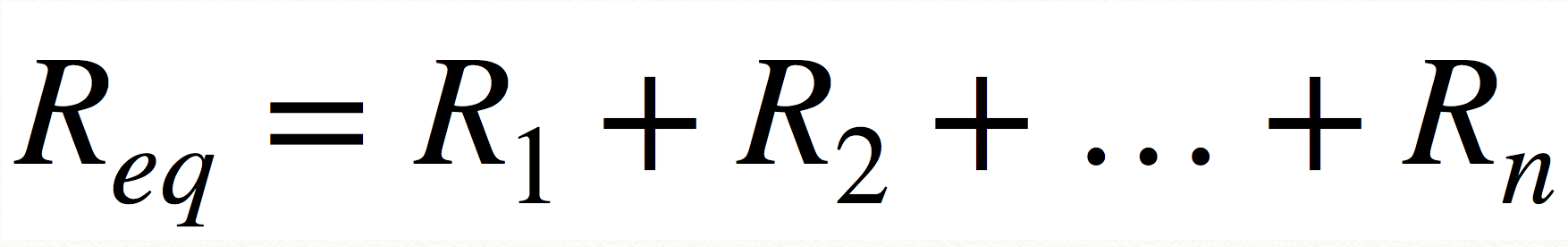

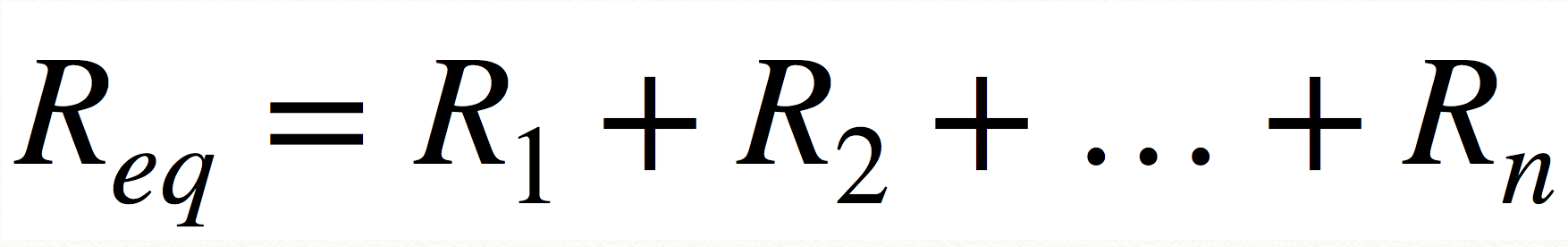

In particular, a system can be characterized by a number of resistors that can occur in series, in parallel or in different combinations. Starting from the simplest cases, in the presence of n resistors in series, or when the terminal node of one resistance represents the initial node of the next, the calculation of the equivalent resistance of the system is quite simple and is obtained through the following formula:

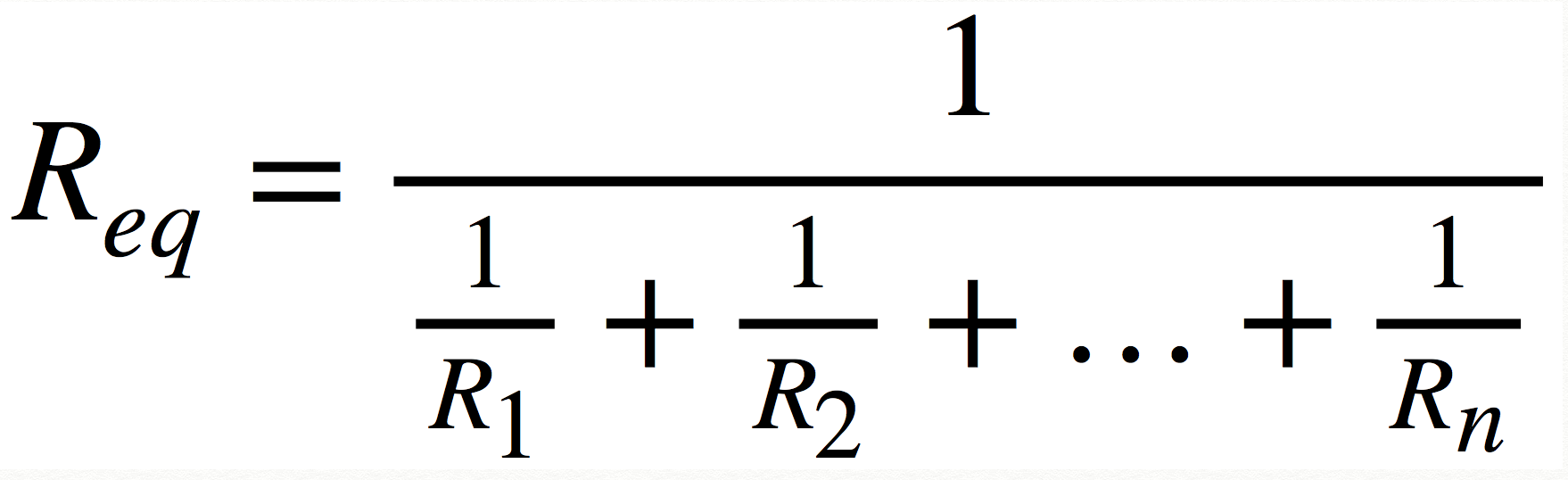

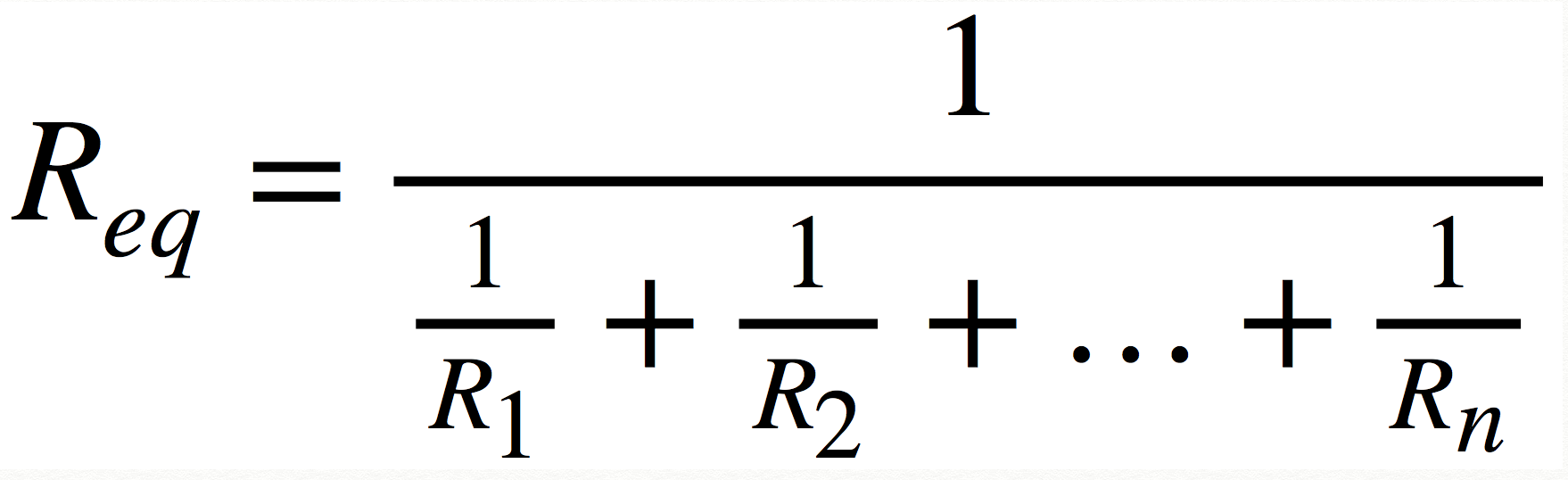

Instead, in the presence of n resistors in parallel, that is, when the start and end node of each resistance is the same, the calculation is slightly more complex and is given by:

In addition, there are an infinite series of intermediate possibilities between the two configurations just seen that can make the calculation much more complex and also require the use of dedicated software.

At the base of the behavior of a circuit in the presence of one or more electrical resistors there are certainly Ohm's laws, which are necessary both for the effective sizing of the system and to be able to calculate the values of the main electrical quantities, the voltage (in Volts) and the current intensity (in Amperes).

In particular, a system can be characterized by a number of resistors that can occur in series, in parallel or in different combinations. Starting from the simplest cases, in the presence of n resistors in series, or when the terminal node of one resistance represents the initial node of the next, the calculation of the equivalent resistance of the system is quite simple and is obtained through the following formula:

Instead, in the presence of n resistors in parallel, that is, when the start and end node of each resistance is the same, the calculation is slightly more complex and is given by:

In addition, there are an infinite series of intermediate possibilities between the two configurations just seen that can make the calculation much more complex and also require the use of dedicated software.

The use of thermostats matched to industrial electrical resistors

In addition to the classic copper resistors (the most used material in the construction of electrical resistances), there are a series of additional devices that are installed in the systems. One of these is the control thermostat, a component mounted directly on the resistance and which manages the power supply according to the temperature. This device is usually made with a polymer with high resistance performance both in the thermal and chemical fields, that is a technopolymer, and through a bimetallic foil, in relation to the temperature of the system, regulates the passage of current.

23/09/2020

I contenuti di questo sito non hanno carattere di periodicità e non rappresentano 'prodotto editoriale'.