Electrical resistances for water heating

Electrical heating resistances used in water heaters and pressure or open boilers

The use of electric heaters is essential where you want to develop the heat necessary for the applications of interest such as, for example, the water heating systems inside domestic systems. The correct design of the systems also involves the study of the most suitable configuration for the arrangement of the resistances used.

What is an electrical resistance?

First of all, when we talk about electrical resistance we refer to a physical size of a body that concerns the tendency to oppose the passage of an electric current when a potential difference is applied. The component of interest for heating systems takes its name from this physical property.

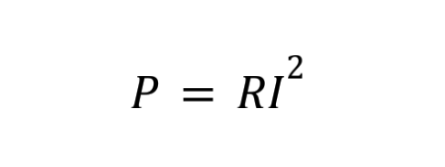

In particular, the most important effect that contributes to the development of heat is called the Joule effect and can be quickly summarized by the following formula:

where P represents the power dissipated in the form of heat in Watts [W], R is the component resistance expressed in Ohm [Ω] and I is the current intensity expressed in Ampere [A].

From this relationship it is possible to easily deduce that there is a linear relationship with the resistance R: the greater the R, the greater the heat developed by the component. In addition, there is a quadratic relationship with the current intensity I.

The study of the circuits and the arrangement of the heating elements can be complicated and requires specific studies in electrical engineering. It is important to note that the resistances can be arranged according to various methodologies:

- In series: the final node of a resistance corresponds to the initial node of the next;

- In parallel: the starting and ending nodes are the same for each resistance;

- Mixed: represents a middle ground between the two provisions.

Furthermore, other components such as inductors and capacitors can be found in the electrical circuit which further complicate the study and implementation of the circuits.

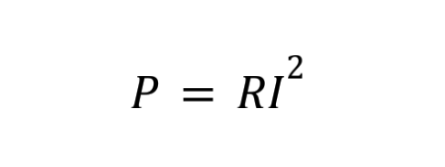

In particular, the most important effect that contributes to the development of heat is called the Joule effect and can be quickly summarized by the following formula:

where P represents the power dissipated in the form of heat in Watts [W], R is the component resistance expressed in Ohm [Ω] and I is the current intensity expressed in Ampere [A].

From this relationship it is possible to easily deduce that there is a linear relationship with the resistance R: the greater the R, the greater the heat developed by the component. In addition, there is a quadratic relationship with the current intensity I.

The study of the circuits and the arrangement of the heating elements can be complicated and requires specific studies in electrical engineering. It is important to note that the resistances can be arranged according to various methodologies:

- In series: the final node of a resistance corresponds to the initial node of the next;

- In parallel: the starting and ending nodes are the same for each resistance;

- Mixed: represents a middle ground between the two provisions.

Furthermore, other components such as inductors and capacitors can be found in the electrical circuit which further complicate the study and implementation of the circuits.

Use of sacrificial anodes for electrical resistances

Sometimes, the electric heaters may find themselves working in contact with hard or particularly aggressive water. In these cases, it is useful to have devices necessary for galvanic protection: the sacrificial anodes. These components are necessary to move the electric potential and must be metals with less electronegativity than that of the resistance. In this way they act as an anode while the resistor acts as a cathode. For example, if you consider the use of iron, some commonly used anodes are magnesium, aluminum and zinc.

This measure is fundamental to guarantee both the safety of the system and of all the people who are nearby, and to increase the durability over time by reducing the maintenance and costs associated with wear over time, compared to a better initial design and slightly higher basic costs.

This measure is fundamental to guarantee both the safety of the system and of all the people who are nearby, and to increase the durability over time by reducing the maintenance and costs associated with wear over time, compared to a better initial design and slightly higher basic costs.

The use of copper for the construction of electrical resistances for the heating system

The electric resistances for heating, as extensively explained previously, are a fundamental component within the circuits used to heat the water inside civil and domestic systems. A fundamental aspect, being components of electrical circuits, is the passage of current inside them. To do this, it is necessary to use high conductivity materials that can make the most of these circuit components, and in full efficiency: among these, the main one is copper.

Characteristics and properties of copper and its alloys

Copper is a sensational material for making electric heating elements as it has unique characteristics that are perfectly suitable for the application:

- High electrical and thermal conductivity: copper is second only to silver from this point of view;

- Ease of processing: it is a ductile and malleable metal, suitable for processes that allow the creation of electrical resistances;

- Corrosion resistance: it is a fundamental feature for application in aggressive and humid environments which over time can lead to the deterioration of many materials.

Furthermore, copper is used in many alloys such as bronzes and brasses, respectively with tin and zinc, in which its characteristics combine with those of other elements allowing to obtain important performances from a mechanical, thermal, chemical and physical point of view.

Characteristics and properties of copper and its alloys

Copper is a sensational material for making electric heating elements as it has unique characteristics that are perfectly suitable for the application:

- High electrical and thermal conductivity: copper is second only to silver from this point of view;

- Ease of processing: it is a ductile and malleable metal, suitable for processes that allow the creation of electrical resistances;

- Corrosion resistance: it is a fundamental feature for application in aggressive and humid environments which over time can lead to the deterioration of many materials.

Furthermore, copper is used in many alloys such as bronzes and brasses, respectively with tin and zinc, in which its characteristics combine with those of other elements allowing to obtain important performances from a mechanical, thermal, chemical and physical point of view.

30/11/2021

I contenuti di questo sito non hanno carattere di periodicità e non rappresentano 'prodotto editoriale'.